Two years after the outbreak of the coronavirus pandemic, the international aviation environment still remains challenging. Although passenger numbers increased again in tandem with the first reopening measures in 2021, the recovery varied considerably from region to region. International travel volumes, in particular, are still considerably lower than before the pandemic. By contrast, continental air traffic and business jet travel are developing very satisfactorily. In general, growth is expected to continue in the medium and long term. Besides increasing passenger numbers, this is also being driven by new mobility concepts and communication channels. FACC has established a pole position in all of these growth markets, and is working intensively on the implementation of its FACC 2030 growth strategy.

In the financial year 2020, FACC assessed its strategy with regard to its technological opportunities. One fact stood out in particular: FACC is, and remains, firmly embedded in the aerospace industry. As a global supplier of turnkey solutions in this business field, FACC is excellently networked and in high demand as a partner. In the past financial year alone, the company secured new orders from international aircraft and engine manufacturers with a total volume of approximately USD 1 billion. In addition, FACC opened two new locations: a Maintenance, Repair and Overhaul (MRO) facility in Florida, and a new production plant in Croatia, which has been focusing primarily on the manufacture of interior components for aircraft since the end of 2021. What is more, the company is continuing on its course of expansion. Over the next few months, FACC will be recruiting 200 new members of staff at its Austrian locations. To accomplish this despite the current shortage of skilled workers, the Group is positioning itself clearly as an employer of choice with a wide range of offers, including unconventional approaches. Under the Bring Your Friend initiative, current employees are encouraged to motivate their friends and relatives to apply for a job at FACC.

The new plant in Croatia will play a major role in this regard as FACC is not only expanding its catchment area, but also establishing a location precisely where manpower is available for its expansion course. Within the last months alone, 150 new jobs have been created at the new Croatian site.

This job initiative is to be accompanied by an investment campaign with a volume of EUR 150 million over the next five years. On the one hand, this is intended to strengthen the Group’s research and development activities with a focus on future lightweight construction technologies and sustainability. At the same time, FACC wishes to step up its growth plans in its core business and new Space and Urban Air Mobility segments.

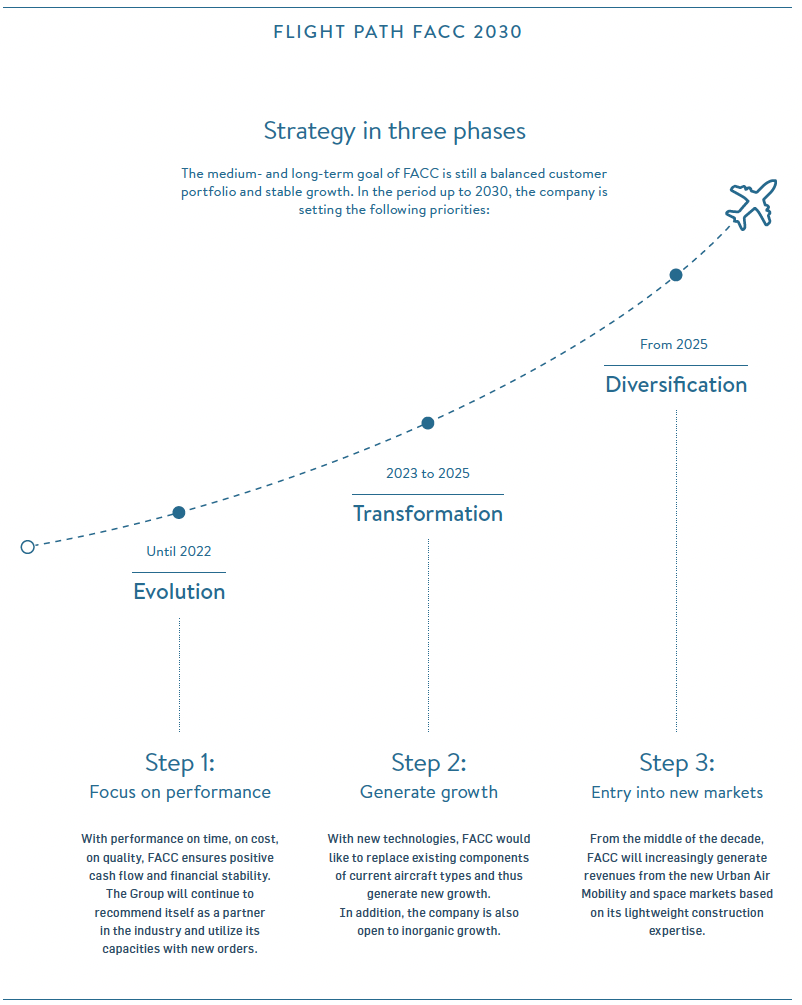

Flight Path 2030: Strategic course set

The job and investment campaign was initiated in response to the upswing in the aviation industry in recent months, and also had a positive impact on FACC’s order books. At the same time, it is also part of the Group’s FACC 2030 strategy, which was presented at the beginning of 2021. In three phases, the company will be substantially expanding its activities by the end of this decade. This not only concerns revenues and market shares in its traditional core business in the aerostructures sector; by 2030, FACC also aims to enter other attractive growth markets, specifically Urban Air Mobility and Space. On this Flight Path 2030, FACC is not only fully on track, but in some cases even clearly ahead of the (interim) targets it has set itself, for instance by securing its first order in the field of space.

Phase 1: Evolution

In the first phase, the drop in sales caused by COVID-19 is to be offset by gaining additional market shares in FACC’s core segment. New orders totaling approximately USD 1 billion in the 2021 financial year and the opening of two new locations constitute important building blocks along this path. The new orders of the past financial year underscore the Group’s high performance and its outstanding market position as a partner to OEMs, supplying them ywith turnkey aircraft components produced using its comprehensive expertise.

Phase 2: Transformation

In the second phase, the aim is to gradually improve existing aircraft fleets, and to replace existing components with new products from FACC, which will contribute to making aircraft systems more efficient while reducing their CO2 and noise emissions. In order to achieve these goals, FACC is currently investing in its manufacturing technology and research capacities. A central focus of its research is on the topic of sustainability. While FACC seeks to further advance its production technologies with a view to increasing energy efficiency, the company is also conducting research on new materials, which can be produced from biological raw materials or recycled. Moreover, manufacturing times are to be shortened, flexibility increased and manufacturing costs reduced through the use of additional high-performance automation technologies.

FACC collaborates closely with its customers in the area of research and development. This is illustrated by the highly successful cooperation with Airbus, in which research is being conducted on future aircraft wings as part of the Wing of Tomorrow project. FACC intends to intensify cooperative research and development ventures of this type in the future.

Phase 3: Diversification

In the third and final phase of its Flight Path 2030 starting in 2025, FACC intends to tap into future markets such as Urban Air Mobility (UAM) and space.

With its joint commitment to the development of passenger drones, FACC has laid the foundation for its activities in the UAM market in recent years; in 2021, FACC added further projects in this field. Moreover, FACC is well ahead of its flight path in the area of space: Since the end of 2021, the company has been developing a central component for the new Ariane 6 launch vehicle on behalf of the European Space Agency (ESA). The first module is scheduled for delivery at the end of 2022. You can find further information on FACC’s first space project on page 10 of this report.

One highlight of FACC’s research and development activities is the expansion of its product range. The PURE CABIN surface coating jointly developed with a partner effectively and sustainably repels viruses, bacteria and fungi, thereby offering passengers even greater protection in aircraft cabins. In addition to laminates, PURE CABIN can also be applied to leather, metal, injection molded parts, fabrics and other materials, where it remains effective for several months. The major advantage for airlines is that cabin surfaces do not have to be disinfected after every flight, with the result that flights can be handled more safely and efficiently.

It therefore comes as no surprise that PURE CABIN has already aroused great interest among aircraft manufacturers and airlines alike. However, completely different areas of application are also conceivable, such as airports, offices, elevators, hotels and all other settings where large numbers of people congregate.